Blog Written by EPS Molders Inc in Edmonton

Table of Contents

ToggleWhat is EPS Foam?

You are probably thinking that this blog is about Styrofoam, which would be the wrong assumption to jump to. Styrofoam is the trademark name for the extruded polystyrene (XPS) blue sheet material. It is manufactured by Dow Chemical through a chemical foaming and extrusion process that uses a number of different gasses and additives that I can’t even pronounce. There is also Pink XPS out there that is manufactured using the same process as Dow Chemicals.

It is this blue and pink Styrofoam that most people think of as destroying the ozone layer. Since the ban on HCFC’s (hydrochlorofluorocarbons) used to manufacture XPS the industry has been scrambling to find new chemicals to replace the HCFC’s that caused so much damage, but many of them have been banned for use recently in Europe and that ban may be coming to North America.

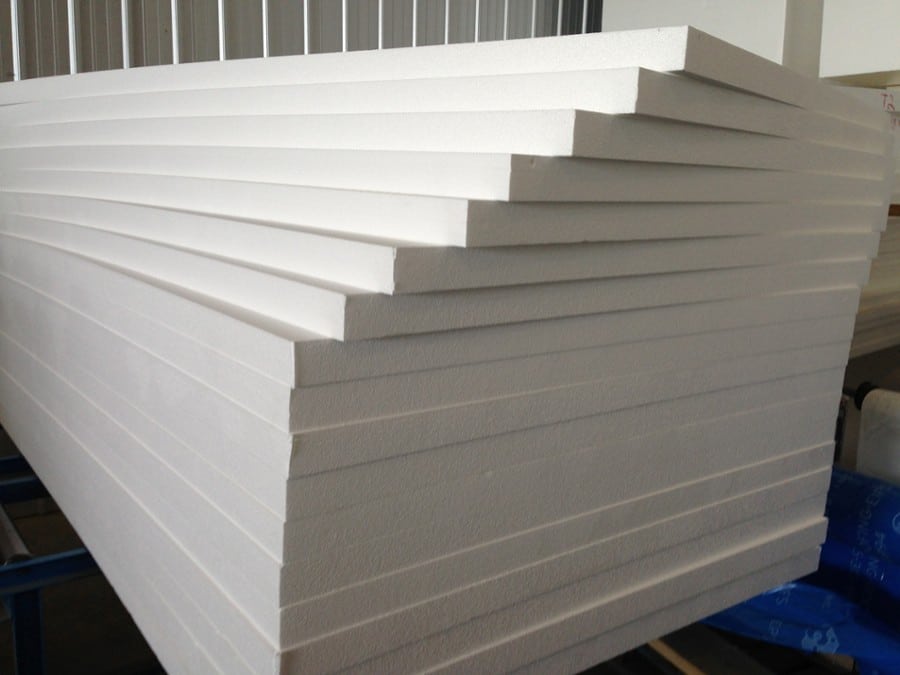

EPS (Expanded Polystyrene) or bead board, is the white stuff. It is used to make coffee cups and the white peanuts that surround the new items you buy online and that are shipped to you. EPS is made with Polystyrene beads and air. There is a small amount of Pentane at the start of the process in the raw bead (2 – 4%) but this is removed when the bead is processed using steam. That is all… steam and pressure used in molds make the EPS. In the end EPS is a 100% totally inert plastic product with no off gassing or emissions to negatively impact your environment.

EPS is Environmentally-Friendly

When understood, that pure end product and environmentally friendly process still doesn’t seem to clear the bad rap that EPS gets from the general public. There is still the HUGE issue that everyone has with it, the fact that it lasts forever, overflows our landfills because it can’t be compressed and, of course, it can’t be recycled… but this is, unfortunately, not the truth.

Every scrap of EPS can be recycled as long as it is clean and free of debris… that’s right every scrap. And it can be done efficiently, using existing technologies and machinery. In fact, huge volumes of EPS are recycled everyday by manufacturers like EPS Molders that make the big volume products like insulation for homes and commercial buildings, roofing systems and EPS Geofoam for use under larger buildings, bridges, roads and dams.

Why use EPS Foam?

These products make houses and commercial buildings that are more energy efficient and last longer, are used to make roads that stand up to frost heaves and can last when built on marshes and soft ground, dampen vibrations that result in premature wear on electrical generators, and pumps and lessening the impact on infrastructure in earthquake prone areas. Overall, in our opinion, EPS contributes more to the positive aspects of environmental responsibility than anything else used in buildings or roads or embankments today.

With new energy codes being introduced and the desire of the end user to have more environmentally responsible and energy efficient homes and buildings, it just makes sense to use a readily available solution to provide better buildings that are also cost effective. EPS is truly an energy saving and energy efficient product.

There are, of course, numerous studies and research articles that can be quoted on EPS’s adaptability, the construction disciplines that use it, why it is better than traditional products in numerous uses, and how it just out performs other products trying to fill the same niche.

But this is to start a conversation about EPS, not be a diatribe of quoted research.

Energy Efficient Insulation Products in Edmonton

In the world, and even in the EPS industry in North American, EPS Molders and many companies like are just dots on the landscape. But we are good dots.

As long as it is clean and free of debris, we recycle 100% of the scrap produced in our manufacturing process and offer a scrap foam recycling program to our clients. We care about the same environment that you do and make products to meet your expectations to be better, cleaner, greener and more responsible future. We have children and grandchildren just like you… and we are concerned about the planet we are leaving them.

Take a minute to see just a few of the products we make https://bit.ly/1Mmwy2L .

If you like what you see follow us on Facebook https://bit.ly/25RpiCf or Twitter https://bit.ly/23kQ07y .

Then search out the EPS manufacturers in your area and follow them as well. Use a search engine and look for EPS insulation or anything similar and read up on it. Then let us know what you think.

This is a great conversation to have and this is just the start.